MANUALE ISTRUZIONE - Telwin MOTOINVERTER 264D CE LOMBARDINI 815980 - Manuale d'uso - Pagina 3

in section

5. INSTALLATION.

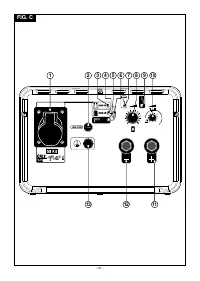

ENGINE-DRIVEN WELDER TO GAIN ACCESS TO THE INSIDE

- Make sure that the voltage of the apparatus corresponds with the

MAKE SURE THAT IT IS SWITCHED OFF.

________________________________________________________________________________

voltage supplied by the auxiliary outlet.

- Connect the plug of the tool to the corresponding outlet on the

If checks are carried out inside the engine-driven welder while it

machine (Fig. C-1).

is live this could cause serious electric shock caused by direct

contact with live parts and/or injury due to direct contact with

- Position the selector to the correct position

(Fig. C-6)

.

moving parts.

________________________________________________________________________________

- Make regular checks, at a frequency depending on the amount of

use and the amount of dust in the surrounding atmosphere,

The engine-driven welder supplies direct current via the

inspecting the inside of the engine-driven welder and using a jet of

auxiliary outlet. It is therefore ONLY possible to connect tools with a

dry compressed air (maximum 10 bar) to remove any dust that has

universal motor (brushes).

been deposited on the transformer, reactance and rectifier.

Examples of such electric tools are:

- Keep the jet of air away from the electronic boards; when necessary,

- Electric drills;

these should be cleaned using a very soft brush and appropriate

- Angle grinders;

solvents.

- Portable jigsaws.

- Take the opportunity to make sure the electrical connections are

- Filament lamps.

tight and that there is no damage to the wiring insulation.

________________________________________________________________________________

- At the end of these operations re-assemble the panels of the engine-

driven welder, tightening the fastening screws right down.

8. USING THE MOTOR-DRIVEN WELDER AS AN AC GENERATOR

- Never, ever, carry out welding operations with the engine-driven

(OPTIONAL)

welder open.

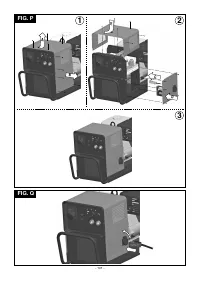

SETTING UP (FIG. P)

10. TRANSPORT AND STORAGE OF THE ENGINE-DRIVEN

________________________________________________________________________________

WELDER

For transport and storage of the engine-driven welder, refer to the

WARNING!

USER'S HANDBOOK provided by the manufacturer of the engine.

All the operations listed below should be carried out with the motor-

driven welder switched off.

11. TROUBLESHOOTING

________________________________________________________________________________

IF THE MACHINE IS NOT WORKING SATISFACTORILY, BEFORE

CARRYING OUT MORE SYSTEMATIC CHECKS OR CONTACTING

- Remove the top and side covers.

THE SERVICING DEPARTMENT, CHECK WHETHER:

- Connect the AC power supply board to the motor-driven welder

- After regulating the welding current using the potentiometer and

using the cable supplied.

referring to the graduated amp scale, the welding current is actually

- Carefully fit the AC power supply kit and the top cover using the

suitable for the diameter and type of electrode being used.

screws for this purpose.

- The yellow LED has lit up indicating triggering of the short circuit

thermal relay.

OPERATION

- Be sure to take note of the rated duty cycle; if the thermal relay

- Make sure the machine is connected to an earth stake as described

triggers wait for the engine-driven welder to cool naturally and make

in chapter

5 INSTALLATION.

sure the fan is working properly.

- Make sure that the voltage of the appliance corresponds with that

- Make sure there is no shorting at the engine-driven welder output

supplied by the AC power supply board.

terminal: if there is a problem, remove the cause.

- Connect the plug of the appliance to the socket provided on the AC

- Make sure the welding circuit connections have been made

power supply

(Fig.Q)

.

correctly; in particular make sure that the earth cable clamp is

actually connected to the piece and that there is no intervening

- Position the selector switch appropriately (

)

(Fig. C-6)

.

insulating material (e.g. Paint).

________________________________________________________________________________

For troubleshooting in the engine refer to the USER'S

WARNING!

HANDBOOK provided by the engine manufacturer.

- The AC power supply board can be used for connecting compatible

If there are problems with the engine contact the nearest engine

electrical appliances, lighting, tools and electric motors that do not

dealer.

exceed the maximum power given in the technical specifications

(TAB. 3).

- The load should be applied after the engine has been started.

- Before switching off the engine, always disconnect the load.

- If the AC power supply board is overloaded or there is a fault in the

_______________(I)_______________

equipment connected to it, the yellow indicator light will come on and

the power supply to the equipment will be cut off.

- Reset is not automatic. To restore the system to operational status

MANUALE ISTRUZIONE

(RESET), it is NECESSARY to follow this procedure:

- Switch off the engine.

- Check the equipment.

- Restart the engine

________________________________________________________________________________

________________________________________________________________________________

ATTENZIONE! PRIMA DI UTILIZZARE LA MOTOSALDATRICE

Connecting the machine to supply electricity to a main

LEGGERE ATTENTAMENTE IL MANUALE DI ISTRUZIONE

supply system in a building is dangerous and absolutely

DELLA MOTOSALDATRICE E QUELLO DEL MOTORE A

forbidden.

SCOPPIO. NON FACENDOLO SI POTREBBERO CAUSARE

________________________________________________________________________________

FERITE A PERSONE O DANNI A IMPIANTI, APPARECCHIATURE

O ALLA MOTOSALDATRICE STESSA.

MOTOSALDATRICI AD INVERTER PER LA SALDATURA MMA E

TIG PREVISTE PER USO INDUSTRIALE E PROFESSIONALE.

9. MAINTENANCE

Nota: Nel testo che segue verrà impiegato il termine “motosaldatrice”.

________________________________________________________________________________

WARNING! BEFORE CARRYING OUT MAINTENANCE

1. NORME DI SICUREZZA GENERALI

OPERATIONS, MAKE SURE THE ENGINE-DRIVEN WELDER IS

SWITCHED OFF.

________________________________________________________________________________

ORDINARY MAINTENANCE

- Controllare il motore prima di ogni uso (vedi il manuale del

ORDINARY MAINTENANCE OPERATIONS CAN BE CARRIED

costruttore del motore a scoppio).

OUT BY THE OPERATOR.

- Non collocare oggetti infiammabili vicino al motore e tenere la

motosaldatrice ad almeno 1 metro da edifici e da altre attrezzature.

ENGINE MAINTENANCE

- Non utilizzare la motosaldatrice in ambienti con pericolo di

Carry out regular maintenance and checks as indicated in the

esposione e/o incendio, in locali chiusi, in presenza di liquidi, gas,

USER'S HANDBOOK provided by the engine manufacturer. For

polveri, vapori, acidi ed elementi infiammabili e/o esplosivi.

oil changes, see also FIG. R .

- Rifornire il motore di carburante in un’area ben ventilata e da fermo. Il

gasolio è altamente infiammabile e può anche esplodere.

- Non riempire troppo il serbatoio del carburante. Nel collo del

EXTRAORDINARY MAINTENANCE

serbatoio non ci deve essere carburante. Controllare che il tappo sia

EXTRAORDINARY MAINTENANCE OPERATIONS SHOULD BE

ben chiuso.

CARRIED OUT ONLY AND EXCLUSIVELY BY EXPERT OR

- Se si versa del carburante fuori del serbatoio, pulirlo bene e

SKILLED ELECTRICAL-MECHANICAL PERSONNEL.

________________________________________________________________________________

permettere ai vapori di dissiparsi prima di accendere il motore.

- Non fumare e non portare fiamme non protette nel luogo dove il

motore viene rifornito di carburante o il gasolio viene conservato.

WARNING! BEFORE REMOVING THE PANELS OF THE

- 6 -

"Caricamento dell'istruzione" significa che è necessario attendere finché il file non è caricato e pronto per la lettura online. Alcune istruzioni sono molto grandi e il tempo di caricamento dipende dalla velocità della tua connessione a Internet.

Altri modelli di generatori Telwin

-

Telwin MOTOINVERTER 204 CE HONDA 815793

Telwin MOTOINVERTER 204 CE HONDA 815793

-

Telwin MOTOINVERTER 254 CE HONDA 815975

Telwin MOTOINVERTER 254 CE HONDA 815975

-

Telwin THUNDER 220 AC HONDA 825001

Telwin THUNDER 220 AC HONDA 825001

-

Telwin THUNDER 304 CE KOHLER 825002

Telwin THUNDER 304 CE KOHLER 825002